Projects

Rail Cars for the mining company C.V.G. Ferrominera Orinoco C. A., in Venezuela delivered under a barter deal, rail cars for iron ore:

With our sister company EIRON GmbH/ Germany, we produced 475 rail bodies in China. They were delivered to Venezuela, where they where assembled with the bogies at the pier in Puerto Ordaz. The boggies where puchased from Holden Inc. in Canada.

Rail car types delivered: 1. Gondolas, 2. Hoppers and 3. Side Dumers;

1. Godola rail car bodies

2. Hopper rail car bodies

3. Discharge of a Side Dumper rail car body

4. Side Dumper rail car bodies assembled with bogies

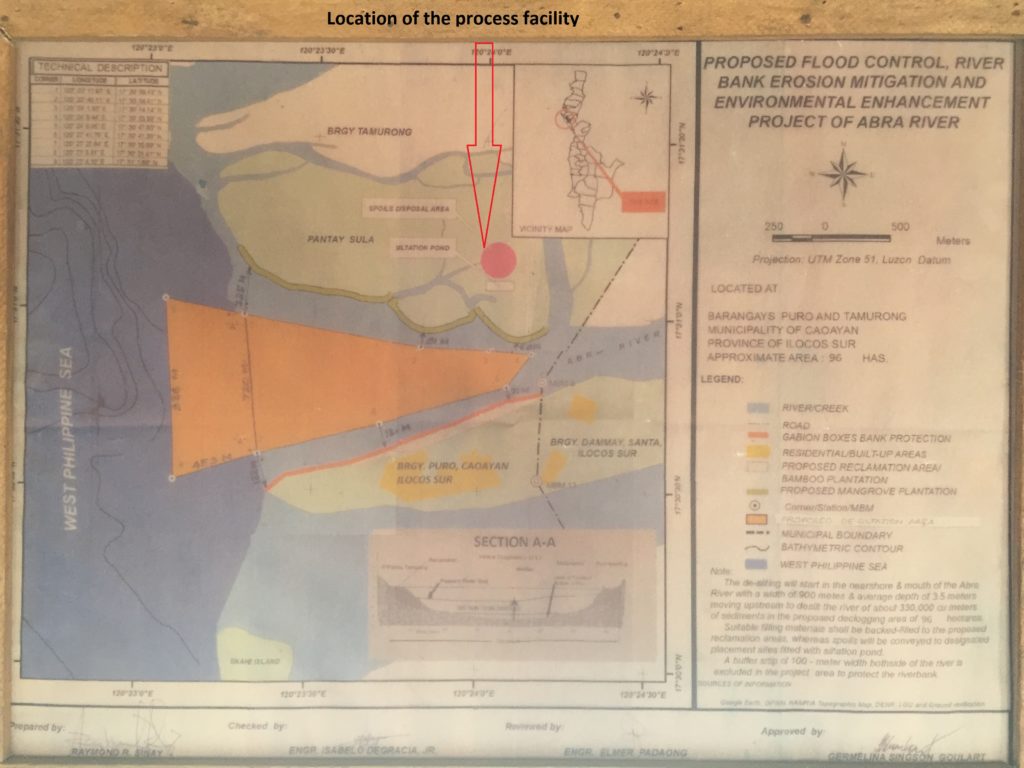

Black Sand processing facility for Eastern Nature Ltd. in Vegan, Philippines.

The process facility has a capacity of 2 million tons per year.

Black sand is dredged from a near by river, as part of a project to allow larger vessels to sail up-river. Then, the black sand is charged to the facility and separated into “iron ore” concentrate and construction sand.

Products are shipped to the iron- and steel industry in China and construction industry in Singapore.

Concession for the river dredging (orange) area and location of the process facility

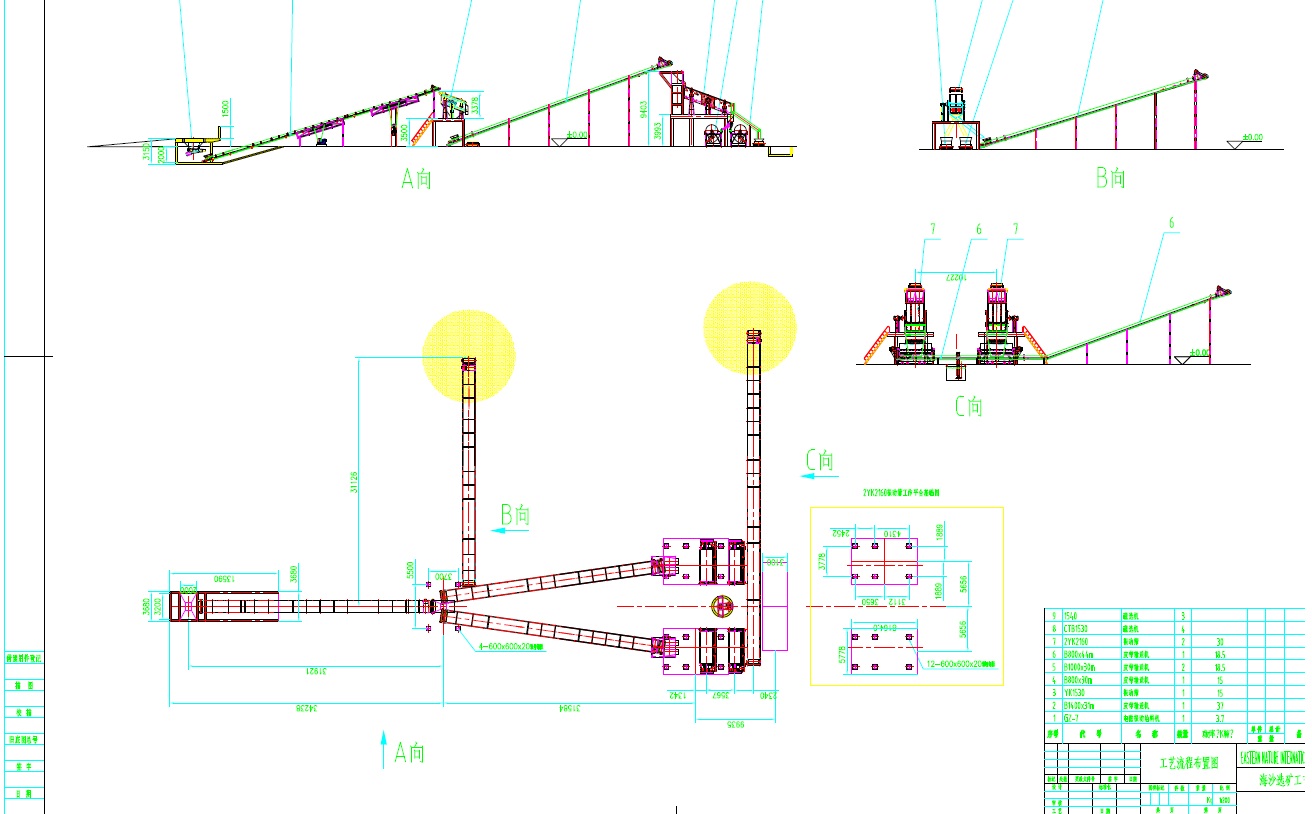

Inhouse design of process facility layout

Process facility under construction

Black sand process

Black sand product

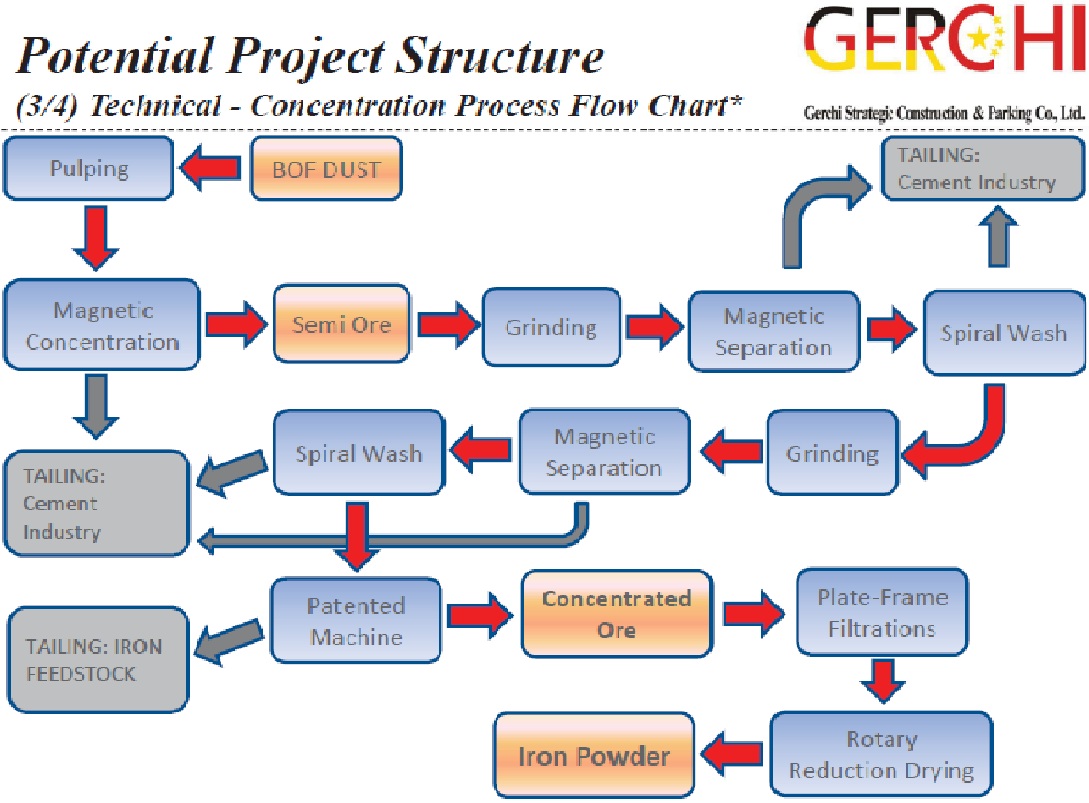

BOF dust recycling project, Topolobampo, Mexico.

3 million tons of BOF dust, as waste accumulated from steel process via converter route, will be recycled.

For this purpose, the dust will be transported from Lazaro Cardenas Port to Topolobampo Port in Mexico.

BOF dust I. and II. stock yard, Lazaro Cardenas, Mexico

Flow chart for the recycling process established for the BOF dust quality from Lazaro Cardenas.

Such flow chart can be adjusted for other BOF dust quallities.

The goal is to produce three products for marketing:

High Fe (plus 97%) powder with different applications, iron ore concentrate (~65% Fe) for pellet making and low Fe material for the cement industry.

Inhouse BOF dust recycling flow chart

Pyrite ash processing to extract gold and other valuable metals.

For this project GERCHI cooperated with a technical partner to construct the process plant in AnHui Province, China.

The pyrite ash is imported from Spain, Portugal and Romania under others.

As the metal extraction does not change the structure of the pyrite ash, the tailings still can be used as a Fe carrier for iron making, or the cement industry.

Pyrite ash stock

The process plant has a capacity of 500mt per day.

Up to Nov. 2017, more than half a million tons of pyrite ash has been processed.

Pyrite ash processing plant, AnHui, China

Refractories relining project for a Steel Plant in South America.

The project contains dozens of different refractories, as for shape and specification.

462 containers of refractories shall be shipped.

Furnace (sample photo)

Refractory bricks (sample photo)

Refractory bricks (sample photo)

Functional refractories and refractory bricks of different specificatons.

Refractory bricks (sample photo)

You have a waste material from the iron- and steel industry, or related industries and you want to clean your waste disposal sites, or works stock yards? You want to recycle waste products in an enviromentally friendly way?

Service

With respect to Raw Materials, Mine & Process, Railways and Projects, we offer different services for our customers and project partners, such as follows:

Raw Materials:

We offer the raw materials, either by way of qualities, we get offered by producers, respectively our principals (what is available for marketing), or by way of qualities, as per the demand of our customers (which qualities are required for the specific production processes at the factories). We have contacts on all continents, the Know-How and relationships to do the sourcing and we can handle the business (from producing the raw material to delivering it to your factory) in a satisfactory and professional manner.

As the case may be, we offer the raw materials based on the following Incoterms:

EXW, FCA, FAS, FOB, CFR, CIF, DAP, DPU, CPT, CIP, DDP

The raw materials and semi-finished products are shipped in minimum quantities of Coastle size vessels, but we ship also in Handy size, Supramax, Panamax and Cape size vessels, as bulk commoditiy, or in containers, depending on the commodity and contract quantity.

Mine & Process:

We work closely with our customers and project partners at the mines to define the right size, specification and quality of eqipment to establish the best quality and value in use for the purpose to be served. Once the demand is clear, we offer the best suitable equipment, competitive prices, timely delivery and proper commissioning (if wanted by the customer) on site. The same counts for process facilities for waste material recycling. If the intended process for the customer, or partner, is established, we offer the best value in use and econominc machinery to serve the purpose. We offer the full service from green-field stage to delivery of the cargo until the process is smoothly up and running.

Railways

We offer all kind of rails cars, as per ASTM or other standards, as well as equipment for the industry.

Projects:

We have our own projects in the mining-, processing- and recycling industries.

In these industries, we also plan, design and layout projects with partners.

However, we also offer the full pallet of services (feasibility studies, product quality design, process design, cash flow projections, CAPEX-CF-OPEX planing, stress tests and marketing reports) to our customers, as the case may be.

Talk to us!

Sebastian & Hongfa